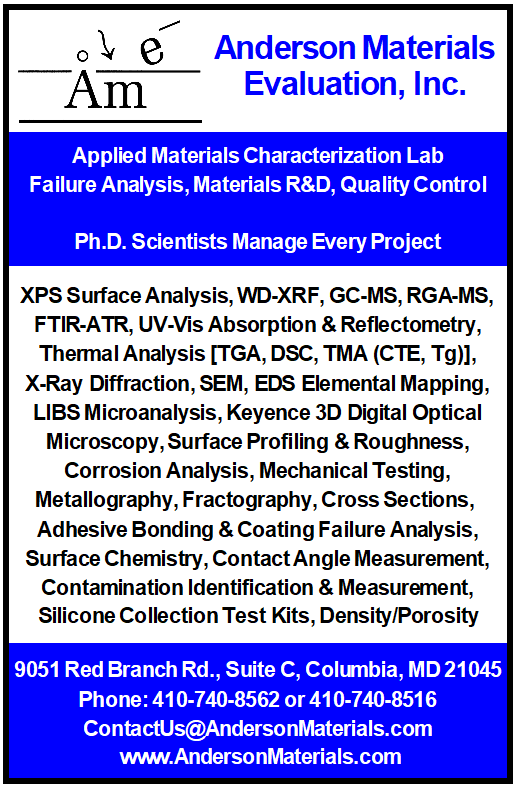

The 14th of July, 2025, is the 30th anniversary of my materials analysis laboratory, Anderson Materials Evaluation, Inc. Within two weeks of the announcement that the recent merger of Lockheed and Martin Marietta was going to result in the closing of the Martin Marietta Laboratories - Baltimore laboratory, I incorporated Anderson Materials Evaluation, Inc.

I initially provided surface analysis services using x-ray photoelectron spectroscopy (XPS, also called electron spectroscopy for chemical analysis or ESCA) and a scanning Auger electron microprobe (SAM). Soon, I added thermal analysis services (thermogravimetry or TGA, differential scanning calorimetry or DSC, thermomechanical analysis or TMA, and dynamic mechanical analysis or DMA) and metallographic microscopy. Down the road awhile, we offered infrared spectroscopy (FTIR) and scanning electron microscopy (SEM). We then added energy-dispersive x-ray spectroscopy (EDS) to our SEM.

Still later, we added mechanical testing capabilities with the purchase of a used Instron machine and we upgraded its electronic controls and software. We purchased an ultraviolet - visible light or UV-Vis spectrometer. Then came the purchase of our gas chromatography - mass spectrometer (GC-MS), followed by the purchase of our wavelength-dispersive x-ray fluorescence spectrometer (XRF). Next, we purchased a 3-dimension high resolution digital optical microscope with surface profiling capabilities and an integrated laser-induced breakdown spectroscopy (LIBS) elemental microanalysis spectrometer. Finally, our last major purchase was our x-ray diffraction instrument (XRD). Through the years, I commonly paid myself less salary than my employees so I could invest more into expanding the laboratory's materials analysis capabilities.

This expanding instrument capability has helped us to provide a wide range of materials characterizations, failure analyses, materials verifications, quality control, detection of hazards, and research and development services. We utilize these capabilities on materials as varied as metals, semiconductors, polymers, glasses, ceramics, composite materials, minerals and other inorganic chemicals, and organic liquids. We presently employ 8 people, counting two interns and two other part time employees.

Today, Howard County, Maryland, presented me with my annual personal property tax bill. My willingness to forgo income, purchase the equipment of my laboratory, and to take on risk, leaves me subject to a large tax bill annually for the value of my laboratory equipment. That equipment depreciates, but if it is in use, it never depreciates below 25% of its initial cost. This is one instance in which inflation is a good thing. At least the expense of purchasing equipment in 1996 is much reduced by the inflation since then, along with the subsequent property tax.

Governments love taking from small businesses. From each according to his ability or capability, to each according to someone's perception of their own need or maybe somebody else's need. The force of government is most easily applied against a minority, such as capable small business owners. Yet, after 30 years, I will continue working for as many more years as I can. I still like solving materials problems and working with the kind of people who share my interest in using materials to improve the condition of mankind.

2 comments:

Charles, I've been working on a science fiction story which involves finding out the effect of 'variable gravity' on materials and even life forms like plants and bacteria. We know how varying temperature and pressure can affect substances such as turning coal into a diamond, but nothing on Earth, other than small centrifuges for short periods of time, allows us to vary gravity.

Space stations have periodically experimented with what happens under 0g. But what about other levels of gravity? Especially if sustained long enough.

In my story, an experimental space station with centrifugal gravity is in Earth orbit and all kinds of substances and some simple life forms are put up there to see what would happen to them at five g's? At 1/5 g? The outermost shell is spinning so as to achieve, day 10G and the gravity of course drops progressively as you move inside toward the center where there's no spin.

Could you have stronger metals? Bacteria which mutate? Chemical reactions which take place differently?

--Phil Coates

It is good to hear from you, Phil.

In my lab, we apply forces greater than 1300 G on materials in our mechanical testing, but that does not give me much insight into your questions. We also use a centrifuge to separate materials for analysis, which has some applicability. Fighter pilots and astronauts train in larger scale centrifuges and there are dramatic effects on their bodies as the G forces are increased. Too little or too much blood or other body fluids can be moved into and out of vital parts of the body.

I would think that if men evolved under greater gravity, that they would have stronger and bulkier bone structure and tend to be shorter. One could ask if the basic chemistry of life would be affected. Deep sea creatures who are subject to very high pressures have the same types of neurons as we do. There RNA and DNA are composed of the same type of proteins, I believe. The basic chemistry of life is not too different. Of course, this science is not the science I have real expertise in. I am just laying out a thought pattern here on which you might do further research. I suspect it is the structures of a living body that change the most if they evolve in greater gravity, but not the basic chemistry of life. You might find the early part of the book A Brief History of Intelligence by Max Bennett of use in thinking about some of these evolutionary issues.

Metals: If anything, their properties likely become harder to control. Additive elements will be harder to distribute evenly and in many alloys, these added elements are there to make an alloy harder or stronger. It may be very slightly harder to maintain vacancies in alloys, which may allow an alloy to have a desired elasticity. However, the coulombic forces that dominate inside a metal are much, much stronger than the force of gravity, so any gravity effects at the 10G level are really small on a metal.

Having directed your attention to deep sea life, the structural effects on life in a non-fluid pressure system with a unidirectional gravity exerted by a floor on life would be very different. On the issue of chemistry, there will be a change in the equilibrium of a gas over a liquid, as an example. The gas pressure for a given number of gas molecules will be greater with greater gravity. A liquid will then dissolve more gas molecules from the atmosphere. A human must then watch out for situations in which the pressure decreases, since bubbles will come out of his fluids and can cause sickness or death. So, your gravity inducing system needs to be reliable or it must at least wind down slowly. Also, no running down the stairs from a 7G level to a 2G level!

Post a Comment