17 March 2005

The Complexity of Reality

The complexity of reality seems a strangely abstract subject for an essay. Why is that of interest to an Objectivist or indeed to anyone? Well, because reality consists of particular existents, or to be less formal, of particular things. Among these things are us and we are extraordinarily particular, or as we say of people, we are very distinguishable as individuals. Now, if we are in the habit of underestimating the complexity of materials, tables, and cows, are we not much more likely to underestimate the complexity of people and their interactions? It is common for people to do just this and Objectivists are sometimes among the most shameless in oversimplifying everything in our quest for tight, simple, logical arguments.

There is a real place for simplification, but we need to retain consciousness of how and why we have performed it in our thinking. As Ayn Rand astutely noted, concept formation depends upon a kind of simplification. It requires that we delete certain measurements of the attributes of things. A table is a table whether it has four legs or three. It may be 4 feet high or it may be 3 feet high. It may be 6 feet long or 12 feet long. Having the concept of a table is valuable to us. It allows us to say, "We need a table for our dining room." Having noted that, we can next consider the particular characteristics that this table should have. We want it to be high enough that we can sit comfortably in chairs around it and yet do not have to reach too high to gain access to our plates. The height of the table can be so chosen. We need to consider how many people should be able to eat at the table at one time. We need to be sure it will fit in the dining room. We had best think about whether it will fit through the doors, so we can put it there. So, as useful as the general concept of table is, we must in many cases put the dimensions of a particular table back into our thinking as we make use of the general concept of a table. As we do that and consider the materials from which it should be made and how they should be processed, we have an individual table again. Finally, as we use it, it will acquire its own set of particular scratches and stains. We live in a world of particular things.

Particular things can be incredibly complicated. Sometimes this seems inconvenient, but actually it is often very essential to our modern technological control of our human environment. Consider the tools that man had to develop in order to gain enough control over the world that his life became less desperate than that of being the prey of lions, tigers, bears, bacteria, and viruses. Without tools, he was subject to the extremes of heat and cold, to the loss of water, and to starvation. At first he had to work very hard to make wood, stone, and bone tools. This was not easy. Making sharp and durable edges from stones is very difficult and tedious work and actually took a lot of skill. Working with wood in all of its varieties was never easy either. But, the varieties in which each material came, did make many applications of these materials possible. But, let us move on to the age of metal use.

The four most common elements in the earth's crust are, starting with the most prevalent, oxygen, silicon, aluminum, and iron. Of these, iron was discovered about 2500 BC. But oxygen was discovered in 1774, silicon in 1824, and aluminum in 1825. For a long time after its discovery, aluminum was more expensive than gold, because it was so hard to unlock from its oxides and other mineral forms. There was no chance of an early Aluminum Age to preceed the Bronze Age. Aluminum was bound up in all kinds of rocks, schists, micas, and clays, but was never found as a vein of pure metal. Fortunately, copper and tin we also discovered in 5000 BC and 2100 BC, respectively. Copper and tin proved relatively easy to work with, so the Bronze Age preceeded the Iron Age. But, copper, tin, and iron are all very soft and of little use for structural purposes in their pure forms. To be useful, one has to have the right additives as in the case for iron and the right mixture of copper and tin in the case of bronze. In the modern era, we use a plethora of iron alloys. Most of these are useful for engineering purposes only when a host of processing conditions are carefully controlled. These alloys are rather complex and often have very individual characteristics that make them suited for the many different applications we have for them.

First, for our more sophisticated uses, we make pure iron, which involves a good deal of processing, which was largely accomplished in the 1800s, but has continued to be improved up to the present time. We now have cast irons such as gray iron, ductile iron, compacted graphite iron, malleable iron, and many alloy cast irons. We have a host of carbon and low-alloy steels as cast steels, hot-rolled steels, cold-finished steels, extruded steels, spring steels, forged steels, bearing steels, dual-phase steels, and ultrahigh-strength steels. There are hardenable steels. There are steels optimized for high temperature use, for neutron radiation resistance, for low-temperature properties, for maximum fatigue resistance, to resist embrittlement in various environments, and to have high toughness. There are wrought tool steels, powder metallurgy tool steels, maraging steels, ferrous powder metallurgy steels, austenitic manganese steels, wrought stainless steels, cast stainless steels, elevated temperature stainless steels, wrought and powder metallurgy superalloys, polycrystalline cast superalloys, and directionally solidified and single-crystal superalloys. All of these are based on iron as the primary ingredient. These hundreds of alloys have a host of individual properties based upon their elemental ingredients, the temperatures they were heated to, the rates at which they were cooled, the manner in which they were beaten, and the order and sequence of all these processes. Iron is alloyed with carbon, manganese, chromium, nickel, vanadium, molybdenum, cobalt, titanium, silicon, phosphorus, sulfur, boron, copper, niobium, zirconium, tungsten, tantalum, aluminum, nitrogen, beryllium, lanthanum, yttrium, hafnium, and selenium to produce various properties.

Engineering metals are usually polycrystalline, with each crystallite called a grain and separated from other grains by a grain boundary. The crystallites consist mostly of very ordered planes of atoms stacked neatly with respect to one another. Iron has chemical phases with carbon called martinsite, austenite, and pearlite. Carbon can be distributed throughout the iron in clusters of graphite. The alloying elements may form various carbide chemical phases distributed in the alloy. The alloying elements may be found preferentially at the grain boundaries or at the metal surface. The size of the grains may be large or small. The grains may be elongated along one axis. The crystallites may have atomic vacancies, interstitial (extra, squeezed) atoms, dislocations (abrupt misalignments within crystallites), twin dislocations, and slip planes. There may also be various intermetallic phases in which the ratio of one element to another is locally precise, but different from areas around it. There is a wealth of possibilities. These materials have a level of complexity that provides us with a huge range of properties and hence of applications of each alloy. We are constantly discovering more useful alloys.

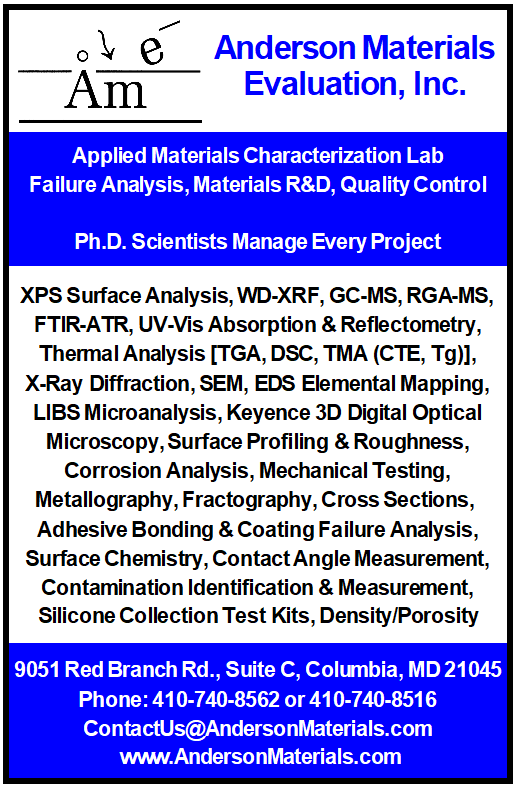

Now, this is just iron alloys. We have copper, nickel, aluminum, titanium, cobalt, tungsten and many other alloys. We also have semiconductor, glass, ceramic, polymer, mineral and inorganic compound, and composite materials. We have thousands of materials and thousands of ways to process them and tens of thousands of ways to use them in thousands of different environments. From the standpoint of an analytical laboratory owner, we investigate materials all the time that are not quite what they are supposed to be. Many errors are made in processing materials to manufacture them to the complex recipes required for each material. Sometimes, fraud and shortcuts were the cause and there are moral implications, but mostly these materials are made well by men operating in a rational environment and still some errors arise. Generally, suspect materials are sent to us for analysis by people who want to produce a good product and they want our help in identifying what is wrong with the material. This is the moral action of rational men. As we proceed in our laboratories to analyze the material we learn more and more about it. Along that path of investigation, however, it is not uncommon for us to have a wrong idea about the implications of our data with respect to the properties of the material. Afterall, materials can be very complex. We simply keep adding up the data from our measurements and observations and try to formulate an idea of the material composition and structure which is compatible with the data we have acquired. Sometimes, we consult with the customer, since he often knows a great deal about his own material and how they have attempted to process it. Faced with all of the complexity of materials and with a considerable complexity in the experimental techniques we use to make measurements and to observe these materials, we have a great deal to sort out and keep track of. We commonly call on multiple members of our staff with training and experience in different fields, with various materials, and with the analytical techniques to make sense of all of the results. In the end, it is amazing how often we figure out what the material is and identify the problem and its cause.

What a wonderful complexity. There is so much richness here that we can support an incredible technological society upon it. The individuality and distinguishability of our engineering materials supports our civilization and makes our lives more security and more likely to be happy. It gives us many opportunities and many choices.

So, if there is so much advantage in the individuality of materials, should we not suspect that there is at least as much advantage in a society of individual men and women? Could it not be that having people of different appearance, experience, athletic abilities, musical abilities, mixes of visual versus aural learning abilities, career interests, reading interests, acting abilities, math and science abilities, favorite sports, disease resistance, dreams, child-raising talents, philosophical beliefs, and sexualities is an advantage to all of the individuals in a society? I find it hard to believe that it would not be an advantage.

However, I constantly observe that many people are certain that anyone different than themselves is not so good as they are. In fact, if they have a different philosophical belief they are likely to be considered evil. By losing sight of the complexity of reality, we lose sight of the reason that people make errors. Even geniuses make errors without having any evil intent. It is also common to condemn those who have a different sexual expression. Apparently, the idea that they are different is unacceptable.

Such judgmental leaps are unfortunately not uncommon among Objectivists, just as they are not uncommon among people who identify themselves with less rational philosophies. Many people are sorely tempted to over-simplify reality and to define the good very tightly and narrowly. It makes thinking about topics easier. In fact, if we simplify enough, maybe we can reduce any complex situation into the equivalent of a situation Ayn Rand addressed and quote her to find the truth. Now we do not have to think for ourselves at all. How convenient. But, we may well have thrown context out the window. We may have made the error of not appreciating the complexity of the situation or person. A terrible consequence is that we lose sight of what makes us individuals and of all the value that comes from that individuality. We have lost the Individualism which is a cornerstone of Objectivism. We have lost much of the richness of experience that makes life so worth living.

There is a real place for simplification, but we need to retain consciousness of how and why we have performed it in our thinking. As Ayn Rand astutely noted, concept formation depends upon a kind of simplification. It requires that we delete certain measurements of the attributes of things. A table is a table whether it has four legs or three. It may be 4 feet high or it may be 3 feet high. It may be 6 feet long or 12 feet long. Having the concept of a table is valuable to us. It allows us to say, "We need a table for our dining room." Having noted that, we can next consider the particular characteristics that this table should have. We want it to be high enough that we can sit comfortably in chairs around it and yet do not have to reach too high to gain access to our plates. The height of the table can be so chosen. We need to consider how many people should be able to eat at the table at one time. We need to be sure it will fit in the dining room. We had best think about whether it will fit through the doors, so we can put it there. So, as useful as the general concept of table is, we must in many cases put the dimensions of a particular table back into our thinking as we make use of the general concept of a table. As we do that and consider the materials from which it should be made and how they should be processed, we have an individual table again. Finally, as we use it, it will acquire its own set of particular scratches and stains. We live in a world of particular things.

Particular things can be incredibly complicated. Sometimes this seems inconvenient, but actually it is often very essential to our modern technological control of our human environment. Consider the tools that man had to develop in order to gain enough control over the world that his life became less desperate than that of being the prey of lions, tigers, bears, bacteria, and viruses. Without tools, he was subject to the extremes of heat and cold, to the loss of water, and to starvation. At first he had to work very hard to make wood, stone, and bone tools. This was not easy. Making sharp and durable edges from stones is very difficult and tedious work and actually took a lot of skill. Working with wood in all of its varieties was never easy either. But, the varieties in which each material came, did make many applications of these materials possible. But, let us move on to the age of metal use.

The four most common elements in the earth's crust are, starting with the most prevalent, oxygen, silicon, aluminum, and iron. Of these, iron was discovered about 2500 BC. But oxygen was discovered in 1774, silicon in 1824, and aluminum in 1825. For a long time after its discovery, aluminum was more expensive than gold, because it was so hard to unlock from its oxides and other mineral forms. There was no chance of an early Aluminum Age to preceed the Bronze Age. Aluminum was bound up in all kinds of rocks, schists, micas, and clays, but was never found as a vein of pure metal. Fortunately, copper and tin we also discovered in 5000 BC and 2100 BC, respectively. Copper and tin proved relatively easy to work with, so the Bronze Age preceeded the Iron Age. But, copper, tin, and iron are all very soft and of little use for structural purposes in their pure forms. To be useful, one has to have the right additives as in the case for iron and the right mixture of copper and tin in the case of bronze. In the modern era, we use a plethora of iron alloys. Most of these are useful for engineering purposes only when a host of processing conditions are carefully controlled. These alloys are rather complex and often have very individual characteristics that make them suited for the many different applications we have for them.

First, for our more sophisticated uses, we make pure iron, which involves a good deal of processing, which was largely accomplished in the 1800s, but has continued to be improved up to the present time. We now have cast irons such as gray iron, ductile iron, compacted graphite iron, malleable iron, and many alloy cast irons. We have a host of carbon and low-alloy steels as cast steels, hot-rolled steels, cold-finished steels, extruded steels, spring steels, forged steels, bearing steels, dual-phase steels, and ultrahigh-strength steels. There are hardenable steels. There are steels optimized for high temperature use, for neutron radiation resistance, for low-temperature properties, for maximum fatigue resistance, to resist embrittlement in various environments, and to have high toughness. There are wrought tool steels, powder metallurgy tool steels, maraging steels, ferrous powder metallurgy steels, austenitic manganese steels, wrought stainless steels, cast stainless steels, elevated temperature stainless steels, wrought and powder metallurgy superalloys, polycrystalline cast superalloys, and directionally solidified and single-crystal superalloys. All of these are based on iron as the primary ingredient. These hundreds of alloys have a host of individual properties based upon their elemental ingredients, the temperatures they were heated to, the rates at which they were cooled, the manner in which they were beaten, and the order and sequence of all these processes. Iron is alloyed with carbon, manganese, chromium, nickel, vanadium, molybdenum, cobalt, titanium, silicon, phosphorus, sulfur, boron, copper, niobium, zirconium, tungsten, tantalum, aluminum, nitrogen, beryllium, lanthanum, yttrium, hafnium, and selenium to produce various properties.

Engineering metals are usually polycrystalline, with each crystallite called a grain and separated from other grains by a grain boundary. The crystallites consist mostly of very ordered planes of atoms stacked neatly with respect to one another. Iron has chemical phases with carbon called martinsite, austenite, and pearlite. Carbon can be distributed throughout the iron in clusters of graphite. The alloying elements may form various carbide chemical phases distributed in the alloy. The alloying elements may be found preferentially at the grain boundaries or at the metal surface. The size of the grains may be large or small. The grains may be elongated along one axis. The crystallites may have atomic vacancies, interstitial (extra, squeezed) atoms, dislocations (abrupt misalignments within crystallites), twin dislocations, and slip planes. There may also be various intermetallic phases in which the ratio of one element to another is locally precise, but different from areas around it. There is a wealth of possibilities. These materials have a level of complexity that provides us with a huge range of properties and hence of applications of each alloy. We are constantly discovering more useful alloys.

Now, this is just iron alloys. We have copper, nickel, aluminum, titanium, cobalt, tungsten and many other alloys. We also have semiconductor, glass, ceramic, polymer, mineral and inorganic compound, and composite materials. We have thousands of materials and thousands of ways to process them and tens of thousands of ways to use them in thousands of different environments. From the standpoint of an analytical laboratory owner, we investigate materials all the time that are not quite what they are supposed to be. Many errors are made in processing materials to manufacture them to the complex recipes required for each material. Sometimes, fraud and shortcuts were the cause and there are moral implications, but mostly these materials are made well by men operating in a rational environment and still some errors arise. Generally, suspect materials are sent to us for analysis by people who want to produce a good product and they want our help in identifying what is wrong with the material. This is the moral action of rational men. As we proceed in our laboratories to analyze the material we learn more and more about it. Along that path of investigation, however, it is not uncommon for us to have a wrong idea about the implications of our data with respect to the properties of the material. Afterall, materials can be very complex. We simply keep adding up the data from our measurements and observations and try to formulate an idea of the material composition and structure which is compatible with the data we have acquired. Sometimes, we consult with the customer, since he often knows a great deal about his own material and how they have attempted to process it. Faced with all of the complexity of materials and with a considerable complexity in the experimental techniques we use to make measurements and to observe these materials, we have a great deal to sort out and keep track of. We commonly call on multiple members of our staff with training and experience in different fields, with various materials, and with the analytical techniques to make sense of all of the results. In the end, it is amazing how often we figure out what the material is and identify the problem and its cause.

What a wonderful complexity. There is so much richness here that we can support an incredible technological society upon it. The individuality and distinguishability of our engineering materials supports our civilization and makes our lives more security and more likely to be happy. It gives us many opportunities and many choices.

So, if there is so much advantage in the individuality of materials, should we not suspect that there is at least as much advantage in a society of individual men and women? Could it not be that having people of different appearance, experience, athletic abilities, musical abilities, mixes of visual versus aural learning abilities, career interests, reading interests, acting abilities, math and science abilities, favorite sports, disease resistance, dreams, child-raising talents, philosophical beliefs, and sexualities is an advantage to all of the individuals in a society? I find it hard to believe that it would not be an advantage.

However, I constantly observe that many people are certain that anyone different than themselves is not so good as they are. In fact, if they have a different philosophical belief they are likely to be considered evil. By losing sight of the complexity of reality, we lose sight of the reason that people make errors. Even geniuses make errors without having any evil intent. It is also common to condemn those who have a different sexual expression. Apparently, the idea that they are different is unacceptable.

Such judgmental leaps are unfortunately not uncommon among Objectivists, just as they are not uncommon among people who identify themselves with less rational philosophies. Many people are sorely tempted to over-simplify reality and to define the good very tightly and narrowly. It makes thinking about topics easier. In fact, if we simplify enough, maybe we can reduce any complex situation into the equivalent of a situation Ayn Rand addressed and quote her to find the truth. Now we do not have to think for ourselves at all. How convenient. But, we may well have thrown context out the window. We may have made the error of not appreciating the complexity of the situation or person. A terrible consequence is that we lose sight of what makes us individuals and of all the value that comes from that individuality. We have lost the Individualism which is a cornerstone of Objectivism. We have lost much of the richness of experience that makes life so worth living.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment